Flat bottom pouches are one of the most premium and versatile packaging formats available today—but customizing them requires more than just picking a shape and size. From barrier materials to printing methods and reseal features, every choice impacts your product’s performance on the shelf and in the consumer’s hands.

The smartest brands don’t just design for looks—they customize flat bottom pouches to protect, perform, and persuade.

Every element of your pouch matters—material, printing, and features must work together to deliver both function and beauty.

What Materials Work Best For Flat Bottom Pouches?

The wrong material can ruin the customer experience. From greasy surfaces to soggy snacks, poor choices can cost you more than just money.

Your material choice is the foundation of your pouch. It determines shelf life, print clarity, recyclability, and even how the pouch feels in the customer’s hands.

Common Material Structures for Flat Bottom Pouches:

| Material Structure | Key Features | Best For |

|---|---|---|

| PET / AL / PE | High barrier, premium look, strong durability | Coffee, snacks, powders |

| PET / MPET / PE | Excellent barrier, cost-effective alternative | Pet food, grains, dry goods |

| Kraft Paper / VMPET / PE | Natural texture, moderate barrier, eco-friendly | Organic products, specialty food |

| Recyclable PE Mono-Material | Eco-conscious, evolving barrier performance | Sustainability-focused brands |

Material selection needs to align with the sensitivity of your product. For example, oxygen- and moisture-sensitive products like coffee or granola perform best in high-barrier films. If sustainability is your main message, kraft paper laminates or recyclable PE films strike the right balance between appearance and eco-friendliness.

Why Do Material Choices Affect Your Product’s Shelf Life?

If your packaging lets in oxygen or moisture, your product will go stale before it even reaches your customer. That’s bad for your brand.

A well-chosen material structure will extend your product’s shelf life, reduce waste, and enhance consumer satisfaction.

Shelf Life Impact Factors:

- Oxygen Transmission Rate (OTR): A lower number means less oxygen gets in—important for oils, nuts, and coffee.

- Water Vapor Transmission Rate (WVTR): Critical for snacks, powders, and baked goods.

- Seal Integrity: Multilayer laminates like PET/AL/PE maintain stronger seals and prevent leaks.

Let’s take coffee as an example. Coffee releases CO₂ after roasting but must be kept away from oxygen. A pouch with AL foil, a degassing valve, and good seals can keep it fresh for 12–18 months. A kraft pouch without barrier layers might only protect it for 2–3 months.

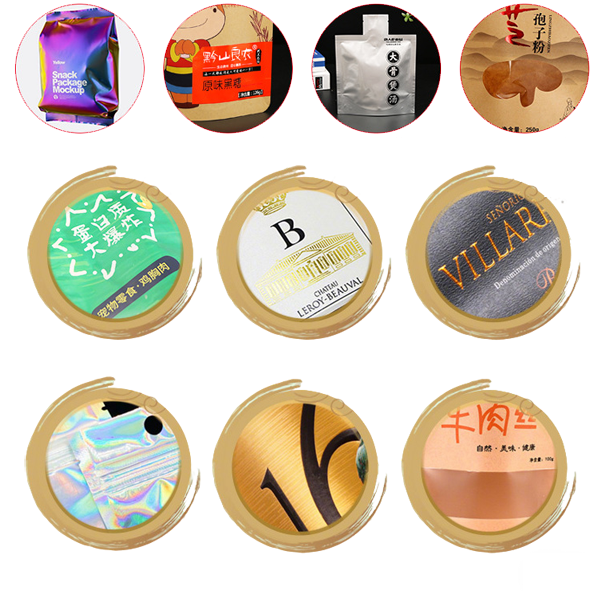

How Do Different Printing Methods Impact Your Design?

You can have the best pouch shape and materials—but if your design looks low quality, your product will be judged the same way.

Your flat bottom pouch can be a canvas for storytelling—if the print method supports it.

Common Printing Technologies for Flat Bottom Pouches:

| Printing Type | MOQ | Color Accuracy | Surface Finish Options | Cost Efficiency |

|---|---|---|---|---|

| Gravure | 5,000+ | Excellent | Matte, gloss, metallic | Best for large runs |

| Digital Printing | Low MOQ | Very good | Matte, gloss | Ideal for short runs |

| Flexographic | Medium | Good | Basic finishes | Budget-friendly option |

Gravure printing gives you crisp, high-resolution branding with rich color and specialty effects like metallics. Digital is perfect for test runs or seasonal packaging. Flexographic is great for simpler graphics and high-volume SKUs.

Your design complexity should guide your print choice. For luxury brands or export goods, gravure is often worth the investment. For local artisan brands, digital printing allows flexibility and speed.

Which Features Should You Add For Maximum Functionality?

A pouch that looks good but doesn’t work well will frustrate customers. Features turn packaging from a bag into a branded experience.

Flat bottom pouches stand out visually—but they can also be high-performance packages with the right features.

Functional Add-ons to Consider:

| Feature | Purpose | Ideal Use Case |

|---|---|---|

| Zipper | Resealability | Snacks, pet food, coffee |

| Tin Tie | Easy resealing with vintage feel | Artisan coffee, loose-leaf tea |

| Degassing Valve | Releases CO₂ while keeping oxygen out | Freshly roasted coffee |

| Tear Notch | Easy opening without scissors | Convenience-focused products |

| Hang Hole | Retail display flexibility | Lightweight snacks, samples |

| Transparent Window | Product visibility, enhances trust | Granola, candy, dried fruits |

Think about how your customers use your packaging. If they’re grabbing snacks on the go, make it easy to reseal. If you’re targeting upscale buyers, a tin tie and custom valve build a premium impression.

Don’t add features just to add them. Choose what aligns with how your customers store, open, and re-use your products.

Conclusion

Every detail—from film type to zipper style—impacts your flat bottom pouch’s performance, shelf appeal, and success in the market.