You see stand up pouches everywhere—from snacks to coffee—but do you really know what they’re made of?

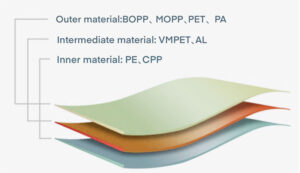

Stand up pouches are made from layers of plastic films, sometimes combined with foil or paper, that are laminated together to provide strength, barrier, and flexibility.

These pouches may look simple, but they're engineered to protect the contents inside. Each layer has a specific job: keeping out air, locking in freshness, sealing tight, and standing upright on the shelf.

Are stand up pouches eco-friendly?

Sustainability is a hot topic—but not all “green” pouches are created equal.

Traditional stand up pouches are not very eco-friendly because they use multi-layer laminated structures. But recyclable mono-material and compostable options are becoming more available.

Over the past few years, I’ve seen a sharp increase in customers asking for sustainable alternatives. Most conventional pouches use different types of plastic—or plastic plus aluminum—which makes recycling nearly impossible. But now, brands are moving to single-material pouches like PE/PE or PP/PP.

Comparing Eco-Friendliness of Different Pouch Materials

| Material Structure | Recyclable? | Compostable? | Barrier Performance | Cost |

|---|---|---|---|---|

| PET/AL/PE | No | No | Excellent | Moderate |

| PET/PE (laminated) | No | No | Good | Lower |

| PE/PE mono-material | Yes | No | Medium | Competitive |

| PLA-based compostable | No (unless industrially composted) | Yes | Low to medium | Higher |

For customers who prioritize eco-friendliness, I recommend PE/PE or kraft paper with water-based coatings. They’re easier to recycle and don’t compromise too much on performance.

What is the structure of a stand up pouch?

A pouch looks flat when empty—but it’s a small engineering marvel when full.

The structure of a stand up pouch includes multiple laminated layers, a bottom gusset, side seals, and a resealable zipper or spout depending on the use.

The strength and functionality of a pouch come from its structure. The lamination makes the material strong and flexible. The bottom gusset expands to support upright display. And optional features like zippers or spouts add convenience.

Basic Structure Breakdown

| Part of Pouch | Function |

|---|---|

| Outer Layer (PET) | Print surface, shape retention |

| Middle Layer | Barrier (often foil or nylon) |

| Inner Layer (PE) | Food-safe sealant layer |

| Bottom Gusset | Helps pouch stand up |

| Zipper/Spout | Resealability, pour control |

Sometimes, the middle layer includes EVOH or metalized PET for added oxygen and moisture barrier. Each component works together to extend shelf life and protect the product inside.

Are stand up pouches BPA free?

Consumers are right to be cautious about food contact materials.

Yes, most modern stand up pouches are BPA-free, especially those designed for food. Manufacturers use BPA-free films like polyethylene or polypropylene as the sealing layer.

BPA (bisphenol A) was used in older plastics and liners, especially rigid containers. But in flexible packaging, PE and PP—both naturally BPA-free—are the most common food-contact layers. If you’re working with a reputable supplier, the materials will meet FDA and EU safety standards.

BPA-Free Verification

| Component | BPA Presence | Common in Stand-Up Pouches? |

|---|---|---|

| Polyethylene (PE) | No | Yes |

| Polypropylene (PP) | No | Yes |

| Polycarbonate (PC) | Yes | No |

| Epoxy Resins (in cans) | Yes | No |

When clients ask, I always provide a full material data sheet and, if needed, third-party test reports proving BPA-free status. Food safety is non-negotiable.

How are stand up pouches filled?

You’ve got the pouch, now how does the product get inside?

Stand up pouches are usually filled through the top opening, either manually or using automated filling and sealing machines. After filling, the pouch is sealed with heat.

I’ve visited factories using both manual and automated systems. Manual filling is common for small brands or limited SKUs. But for efficiency and hygiene, medium to large food brands invest in form-fill-seal (FFS) or pre-made pouch machines.

Filling Methods for Stand Up Pouches

| Method | Use Case | Speed | Investment |

|---|---|---|---|

| Manual Filling | Startups, short runs | Slow | Low |

| Semi-Automatic | Medium production | Medium | Moderate |

| Fully Automatic FFS | High-speed production lines | Fast | High |

| Spouted Pouch Filling | Liquids, purees | Medium/Fast | Moderate |

Once filled, pouches go through heat sealing at the top to lock in freshness. Some include nitrogen flushing to preserve shelf life. I always advise customers to design the pouch top with enough space to accommodate the sealing bar and filling spout if needed.

Conclusion

Stand up pouches are made of laminated layers of plastic or foil, and can be engineered to be food-safe, recyclable, and resealable—depending on the material choices.