Sometimes it feels like there are too many pouch types to choose from, and the names sound similar—what do they really mean for your product?

Stand up pouches and flat bottom pouches differ in structure, capacity, shelf presence, and cost. Flat bottom pouches stand more firmly and hold more, while stand up pouches are more economical and flexible.

Picking the right pouch isn’t just about looks—it affects how your product sells, ships, and stores. Once you understand how stand up and flat bottom pouches really work, you’ll know what fits your needs best.

What are the different types of standing pouches?

Trying to pick the right pouch? You’ll see terms like “doypack,” “gusset,” or “spout,” but they all fall under the big category of stand-up pouches.

Stand up pouches include doypack pouches, bottom gusset pouches, spouted pouches, zipper pouches, and even shaped pouches. They all have one thing in common—they stand upright when filled.

There are many sub-types of stand up pouches, each tailored for different uses:

Common Stand-Up Pouch Types

| Pouch Type | Key Feature | Ideal For |

|---|---|---|

| Doypack | Rounded bottom gusset | Snacks, powders, coffee |

| Bottom Gusset | Folded gusset at base | Granola, pet treats |

| Spouted Pouch | Built-in pouring spout | Liquids, baby food, juice |

| Zipper Pouch | Resealable with press-to-close zip | Dried fruit, nuts, supplements |

| Shaped Pouch | Customized silhouette | Beverage, kids’ snacks, branding |

I often recommend spouted pouches to clients who package liquids or baby food because they’re safe, resealable, and lightweight. For dry goods, zipper options are the go-to.

What are the advantages of stand up pouches?

Stand up pouches became popular for a reason—they’re light, flexible, and consumer-friendly.

Stand up pouches are lightweight, save space, offer great shelf visibility, and support many add-ons like zippers or spouts—all while keeping packaging costs low.

Let’s break this down. Stand up pouches work well in retail because they combine visibility with low weight and shipping savings. Many of my clients choose them for new product launches because they are budget-friendly and easy to design.

Benefits of Stand Up Pouches

| Benefit | Why It Matters |

|---|---|

| Lightweight | Lower shipping costs |

| Flexible design | Supports branding, spouts, zippers |

| Space-saving | Ships flat, stores easily |

| Good shelf appeal | Stands upright, shows full branding |

| Cost-effective | Lower unit cost than rigid packaging |

When a client has a new snack line and a tight budget, stand up pouches usually give them the best value while keeping things attractive and functional.

What is the difference between a flat pouch and a stand-up pouch?

Sometimes people confuse flat pouches with stand-up ones—but they serve different roles.

Flat pouches do not stand on their own and are usually sealed on three sides. Stand-up pouches have a gusset or bottom fold that lets them sit upright on shelves.

Flat pouches are best when shelf display isn’t important. They work well for single-use items like seasoning packets, sauces, or sample packs. They cost less but don’t provide the visual branding space that a stand-up pouch offers.

Key Differences

| Feature | Stand-Up Pouch | Flat Pouch |

|---|---|---|

| Structure | Has gusset/bottom to stand | No gusset, lays flat |

| Shelf Presence | Excellent | Minimal |

| Branding Space | Front and back, full visibility | Mostly front only |

| Ideal Use | Snacks, pet food, retail items | Samples, small portions |

| Cost | Mid-range | Lower |

If you're packing small sachets for giveaways, I would suggest flat pouches. But if you want your product to pop on a store shelf, go with a stand-up pouch.

What are stand up pouches made of?

Packaging looks simple, but materials make all the difference for food safety and shelf life.

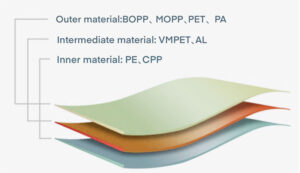

Stand up pouches are made of multi-layer films like PET, PE, BOPP, aluminum foil, or kraft paper. These layers combine to provide durability, printability, and barrier protection.

The materials used in stand up pouches depend on what you’re packaging. If you need moisture or oxygen protection, I would recommend foil or metallized films. For an eco-friendly look, kraft paper layers work well with dry products.

Common Material Structures

| Layer Type | Function | Example Materials |

|---|---|---|

| Outer Layer | Print surface, durability | PET, BOPP, Kraft Paper |

| Middle Layer | Barrier protection (light, moisture, oxygen) | Aluminum Foil, MPET |

| Inner Layer | Food contact layer, heat sealable | PE, CPP |

In most custom jobs, I recommend using a PET/AL/PE structure for products like coffee or snacks. It seals well, keeps flavors fresh, and protects from moisture. If you're looking for eco options, recyclable PE/PE films are getting popular too.

Conclusion

Stand up pouches and flat bottom pouches each offer unique strengths—choose based on product needs, shelf goals, and budget.